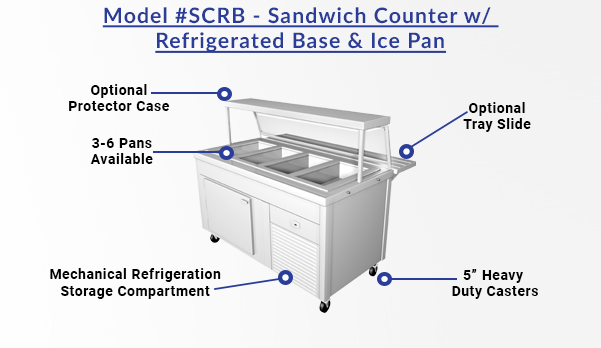

Model #SCRB – A Gateway to Assembling the Perfect Sandwich

If your facility has dining, the chances are very high that sandwiches will be on the menu. In fact, sandwiches are one of the most popular food choices in America. With such high favor, sandwich ingredients need to be paired with the best equipment in order to be prepped & served. Here’s where IMC’s Model #SCRB comes into play.

In this article, we’ll take a deep dive into Model #SCRB & then go over a few advantages of having one in your lineup during service. Let’s jump right in.

Model #SCRB – A Home for Your Sandwich Ingredients

Model #SCRB gives you an avenue for safely housing your sandwich ingredients in a refrigerated environment. In order to maintain freshness, common sandwich ingredients such as lettuce, tomatoes, meats, cheeses, condiments, etc. should be stored in a chilled area during service hours.

SCRB’s top is constructed of 16-gauge stainless steel & the frame is constructed of 14-gauge stainless steel. Both utilize type 300 series stainless steel.

Regarding the mechanical refrigeration, the compartment is cooled with a blower & designed to hold food products for continuous storage. The unit keeps temperatures between 31-41 degrees Fahrenheit. Instead of using drains or valves, a condensate evaporator is utilized. The compressor itself is stored in a louvered housing & easily plugs into any outlet.

Let’s break down SCRB below:

What’s the Big Advantage?

A counter of this type might seem like a simple item, but they are essential if you’re going to be serving sandwiches during dining hours. Let’s look at 3 major benefits of having one in your lineup:

1. Store Your Ingredients – As mentioned, ingredients need to be ready to be assembled quickly. SCRB provides a clean & durable prep surface to create your signature sandwiches during service hours. Thanks to the chilled pans, your ingredients will remain fresh & temperature safe.

2. Boost Your Offerings– You may have other modular serving systems such as hot & cold food counters already in play. With the addition of a dedicated sandwich counter, you open up a wider range of food possibilities for patrons to take advantage of.

3. Customizable for You – IMC modular serving systems can be tailored for any application. Two common options for the sandwich counter are a protector case (to shield from germs/bacteria) & a tray slide (gives your patrons a resting spot for their trays). Other notable options include an intermediate undershelf, work shelf, or a correctional package. If you want a stationary modular counter, consider swapping out the standard casters with legs with bullet feet.

IMC recognizes that equipment should be convenient & easy to use, even during those chaotic service hours. Model #SCRB is designed to handle your entire sandwich serving needs, making it a welcome addition to your modular lineup. For a closer look at IMC’s sandwich counter, click here.