Everything You Need to Know About IMC Wall Caps

It’s a fact of every commercial area that walls are easily the most damaged part of the facility. Heavy vehicular traffic, environmental conditions & defects are the main culprit of this. How can we preserve the walls so our facility looks pristine over time?

In this article, we’ll define what a wall cap is & the primary purpose of them. We’ll also break down IMC’s wall cap product & give you some advantages of using them. Let’s begin.

Why Do Wall Caps Matter?

As stated above, the walls in your facility are more than likely scuffed up or full of noticeable holes. A wall cap’s job is to cover up these damaged spots & add a bit of stability to the existing wall. They do this by simply snapping onto the wall itself.

The long & short of it is they provide the ultimate impact protection for use in kitchens, sanitation or high abuse areas. Without them, there may be further risk of structural failure to your walls & eventually a complete rebuild may be necessary.

As a bonus – wall caps also keep your employees safe from injury preventing any snags or lacerations from compromised walls.

How Do They “Snap” Onto the Wall?

You can use 2 methods:

1. Two-Sided Tape – This is the easiest method of applying wall caps. It is also the simplest way to remove the caps without leaving behind holes. There may be a slight adhesive residue left on the wall, but it can be quickly cleaned away.

2. Countersunk Holes & Screws – This means the screws do not have a head, so there is nothing protruding out from the wall cap itself. This method is common, but if you need to relocate your wall cap, you risk having holes in your wall when it is initially taken down.

IMC Wall Caps – The Ultimate Protection for Your Walls

Now that you are a pro on wall caps, let’s dive into IMC’s wall cap offering, Model #WC.

WC is constructed from 16-gauge type 300 series stainless steel. The edges are kinked allowing for a snug hold onto your wall. Each piece is bent 90°.

Standard width is 8″, the legs are 4″ each & heights range from 48″-96″, but IMC wall caps may be customized to fit your application as necessary.

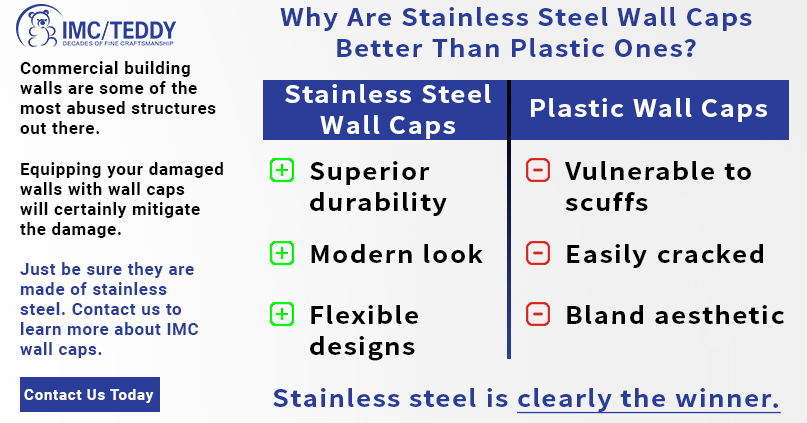

Aside from the safety features, IMC wall caps add that decorative flair to any commercial space. The sleek, modern look of stainless steel beats out plastic competitors. The stainless steel construction is meant to stand the test of time, while cheaper plastic wall caps will wear away & crack eventually.

Here’s a look at IMC wall caps in detail:

Stainless steel wall caps are simply the most efficient way of repairing & safeguarding your walls. The combination of modern aesthetics & durability mean your walls look will spotless for years to come. To learn more about how IMC’s wall caps, click here.